application

Industry application

2025/02/28

Mining crushing and screening equipment

JXL heavy-duty bearings reshape the new durability standard of mining equipment

详细介绍:

JXL heavy-duty bearings reshape the new durability standard of mining equipment

[Core innovator of mining transmission systems]

JXL focuses on the field of heavy-duty mining equipment and provides global mining companies with ultra-strong bearing solutions that meet ISO 3408 standards. Our products have passed the MSHA mining safety certification and are designed for high-impact and dusty working conditions of crushers, vibrating screens and other equipment, helping the equipment to operate continuously for more than 12,000 hours and reduce the failure rate to 0.5 times/thousand hours.

▌Five extreme challenges of mining equipment

Directly hit the core pain points of the industry:

• 2000 tons/hour crushing load impact

• Micro-motion wear caused by basalt/granite

• High humidity dust intrusion (PM100 concentration>200mg/m³)

• 24-hour continuous vibration working conditions (acceleration>8g)

• Extreme temperature difference in the field (-30℃ to 80℃ cyclic impact)

▌Mining-specific bearing technology matrix

JXL four major innovative product systems:

▶ Crusher reinforced bearing group

Tungsten carbide alloy raceway: impact load resistance increased by 300%

Self-cleaning sealing system: dust blocking efficiency > 99.8%

Hydraulic preload device: axial clearance dynamic compensation ±0.05mm

▶ Vibrating screen vibration-resistant unit

Double-row spherical roller bearing: radial load capacity up to 8000kN

Damping alloy cage: vibration energy absorption rate increased by 65%

More Centering design: Compensate for screen installation deviation ±3°

▶ Special bearings for conveying system

Labyrinth triple seal: IP69K dust and water resistance

Graphene lubrication layer: Maintenance-free period extended to 2 years

Anti-lateral force structure: Belt deviation compensation angle ±5°

▶ Intelligent monitoring bearing series

Embedded vibration sensor: Real-time collection of 10 operating parameters

Wear warning system: Predict faults 300 hours in advance

Satellite communication module: Real-time data transmission of unmanned mining areas

▌Typical equipment performance breakthroughs

Technology empowers mining productivity upgrades:

✔ Jaw crusher: single machine processing capacity increased to 3500t/h

✔ Cone crusher: liner replacement cycle extended by 40%

✔ Heavy-duty vibrating screen: screening efficiency exceeds 98.5%

✔ Belt conveyor: continuous operation life reaches 50,000 hours

✔ Mobile crushing station: corrosion resistance verification in hot and humid environment (RH95%)

▌Full life cycle value system

Choosing JXL will get:

✓ Capacity improvement: equipment overall efficiency (OEE) increased by 22%

✓ Safety guarantee: passed ISO 19443 nuclear grade vibration test

✓ Cost optimization: bearing cost per ton of ore processing reduced by 35%

✓ Intelligent management: digital twin system realizes accurate prediction of spare parts

Core product spectrum

• Crusher series: JXL-CR8000 jaw crusher / JXL-HC cone crusher reinforcement group

• Screening equipment group: JXL-VS3600 vibrating screen bearing / JXL-TS dual-axis excitation unit

• Conveying system: JXL-CB5000 conveyor set / JXL-AMC anti-deviation module

• Intelligent monitoring: JXL-IMM intelligent mining bearing / JXL-PHM health management system

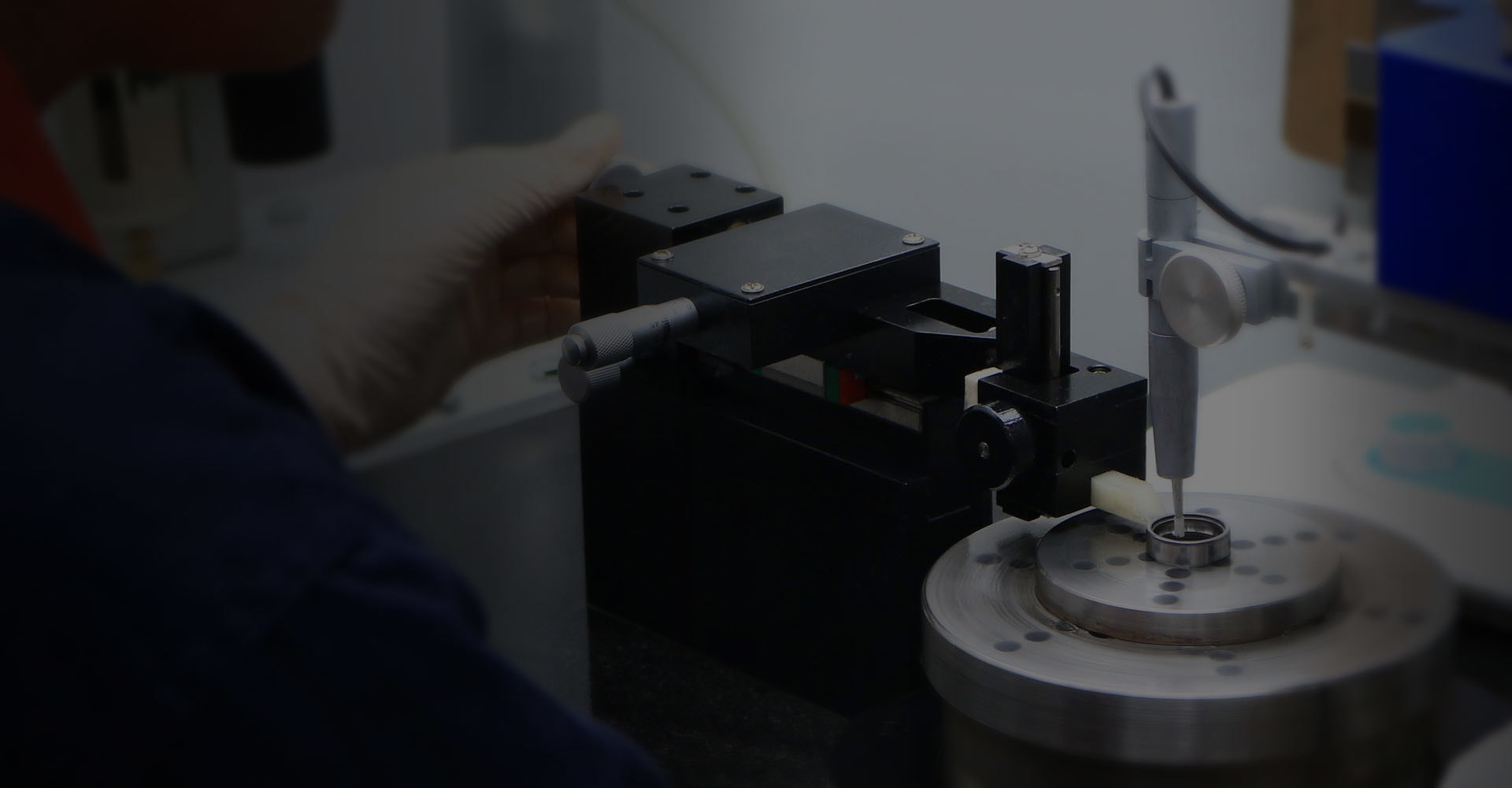

JXL has established a mining equipment research institute equipped with a 3,000-ton dynamic load test bench and a dust accelerated wear laboratory. We provide a full chain of services from mine mapping to equipment modification, and promise 24-hour on-site response for open-pit mine projects, a 3-year/30,000-ton processing volume warranty for key components, and a supporting intelligent operation and maintenance platform to achieve real-time visual monitoring of bearing health.

关键字:

Product

consultation

CONTACT US

Office add: 1304,NO.7-2,Yingpan North Street,Hunnan District,Shenyang,China

Email:junxi@jxlbearing.com

Tel:+8613998875757(Wechat)