application

Industry application

2025/02/28

Chemical equipment

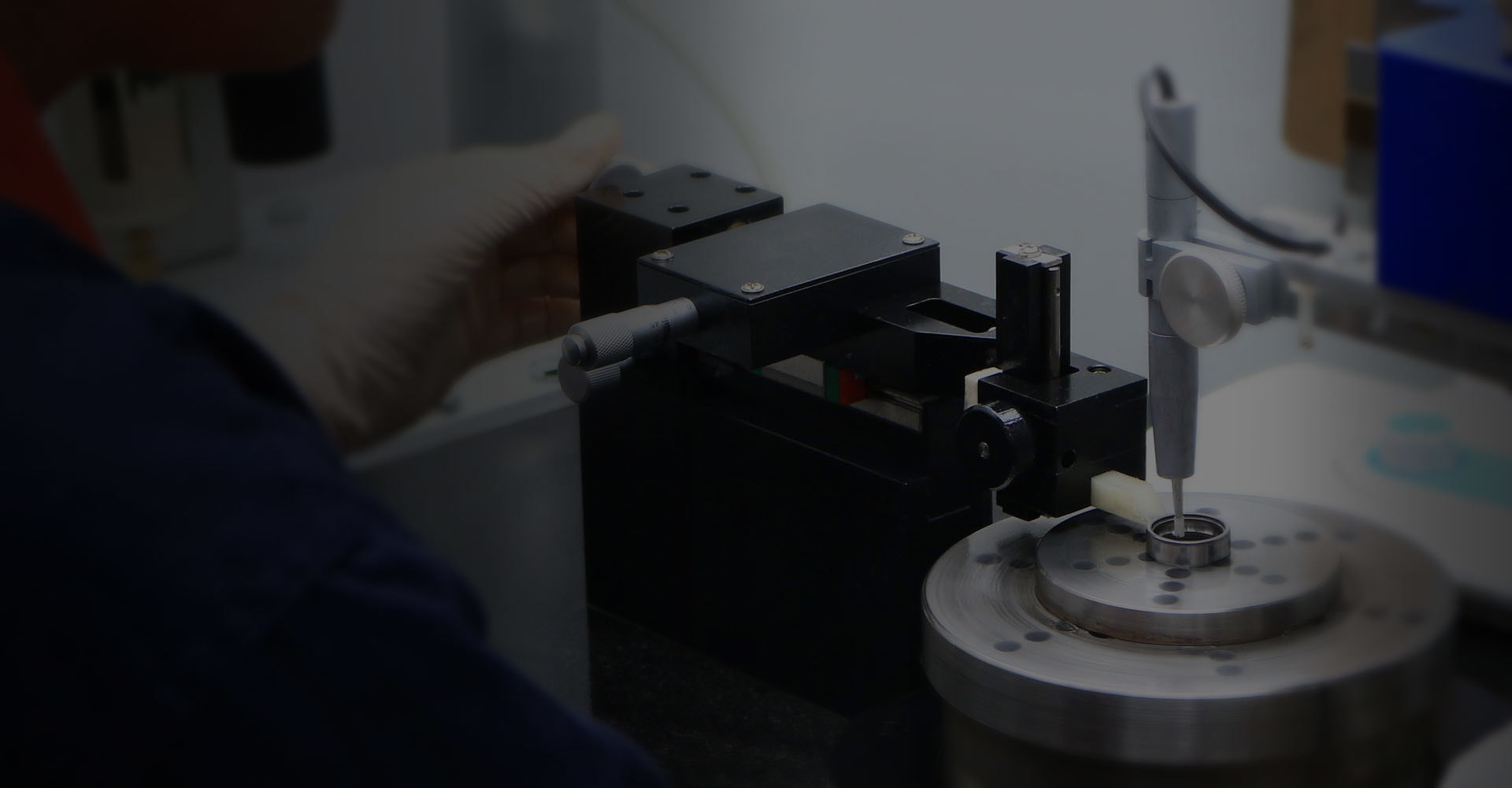

JXL industrial bearings enable efficient operation of chemical equipment

详细介绍:

JXL industrial bearings enable efficient operation of chemical equipment

[Core transmission expert for process industry]

JXL has been deeply involved in the field of chemical equipment for 20 years, providing special bearing solutions that meet API/ASME standards for global petrochemical and fine chemical companies. Our products have passed ISO 15848 anti-leakage certification and ATEX explosion-proof certification, and are designed for extreme working conditions such as high temperature, high pressure, and strong corrosion, helping the equipment to break through the 8,000-hour continuous operation cycle.

▌Five core challenges of chemical equipment

Solving the key pain points of the industry:

• Strong acid/alkaline medium corrosion (pH value 0.5-14 extreme environment)

• 200℃ high temperature + 5MPa high pressure composite working conditions

• Abrasive wear caused by solid particle intrusion

• Safety protection in explosive gas environment

• Zero unplanned downtime under continuous production

▌Special bearing technology matrix

JXL three major innovative product systems:

▶ Corrosion-resistant bearing series

Duplex stainless steel matrix: pitting resistance index PREN>40

PTFE composite coating: 98% concentrated sulfuric acid resistance verified for 3000 hours

Triple labyrinth seal: IP69K protection level, particle blocking rate>99%

▶ High-load crushing bearing group

Tungsten carbide reinforced raceway: 200% increase in impact load resistance

Self-repairing lubrication system: wear compensation accuracy 0.01mm

Hydraulic locking device: intelligent adjustment of axial preload

▶ Sealing anti-leakage unit

Airtight dynamic seal: leakage rate<10^-6 Pa·m³/s

Magnetic fluid isolation technology: realize zero contact with media

Online monitoring interface: real-time transmission of vibration/temperature data

▌Breakthrough in typical equipment applications

Technology drives process industry upgrades:

✔ Reactor mixer: withstand long-term operation in 20% hydrofluoric acid environment

✔ Centrifugal compressor: ultra-high speed and stable operation at 25,000rpm

✔ Screw pump system: achieve 0.1μm-level sealing protection

✔ Ball mill crusher: single maintenance cycle extended to 18,000 hours

✔ Flue gas desulfurization equipment: 150℃ wet chlorine corrosion resistance verification

▌Full value chain benefit system

Choosing JXL will get:

✓ Safety compliance: meet SIL3 safety level and TA-Luft standards

✓ Energy efficiency improvement: transmission loss reduced by 30%, annual electricity saving of more than 150,000 degrees

✓ Cost optimization: maintenance cycle extended by 3 times, spare parts consumption reduced by 45%

✓ Intelligent operation and maintenance: equipped with IoT sensors to achieve predictive maintenance

Core product spectrum

• Corrosion-resistant series: JXL-CR680Hast / JXL-PTFE-XT coating unit

• High-load series: JXL-HL5000 crusher special bearing group

• Sealed series: JXL-SMAG magnetic fluid sealed bearing / JXL-ATEX explosion-proof unit

• Smart series: JXL-IoT4.0 sensor bearing / JXL-DMS digital twin system

JXL has established a chemical equipment technology center, equipped with a high-temperature and high-pressure corrosion test chamber and a 100,000-hour life acceleration test platform. We provide full technical services from material selection to failure analysis, promise 48-hour emergency response for EPC projects, and provide 5-year/100,000-hour ultra-long warranty for key components, helping chemical companies achieve the goal of long-term operation of the device.

关键字:

Product

consultation

CONTACT US

Office add: 1304,NO.7-2,Yingpan North Street,Hunnan District,Shenyang,China

Email:junxi@jxlbearing.com

Tel:+8613998875757(Wechat)